Prestressed Wall Panels are a Tried and Tested European Construction Technique. They are used widely throughout Europe for a wide variety of applications including storage bays, silage bunkers, and farm sheds.

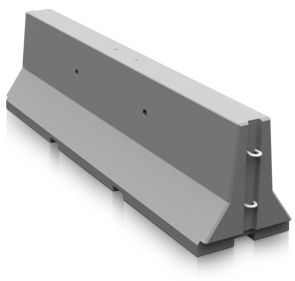

They are long thick panels of concrete that contain prestressed steel cables. The panels vary in height from 1 to 1.5 m and in length up to 6.1 m. They are 140 mm thick and contain 7 strands of prestressed steel.

There are tongue and groove joints along the horizontal edges so the panels slot into one another. They are placed between vertical Steel columns (RSJ’s ) to form walls.

As the panels have prestressed steel, they can form stronger walls with less material.

There is no need for Shuttering, block laying or plastering. Thus, Labour costs are significantly reduced.

They are manufactured offsite inside a controlled environment leading to a durable high-quality finish so no onsite curing is required.

Consequently, they are delivered ready for immediate use regardless of the weather conditions.

Lifting inserts are placed in the panels to aid installation so they are Fast and Easy to install and they Can be repositioned or removed when required.